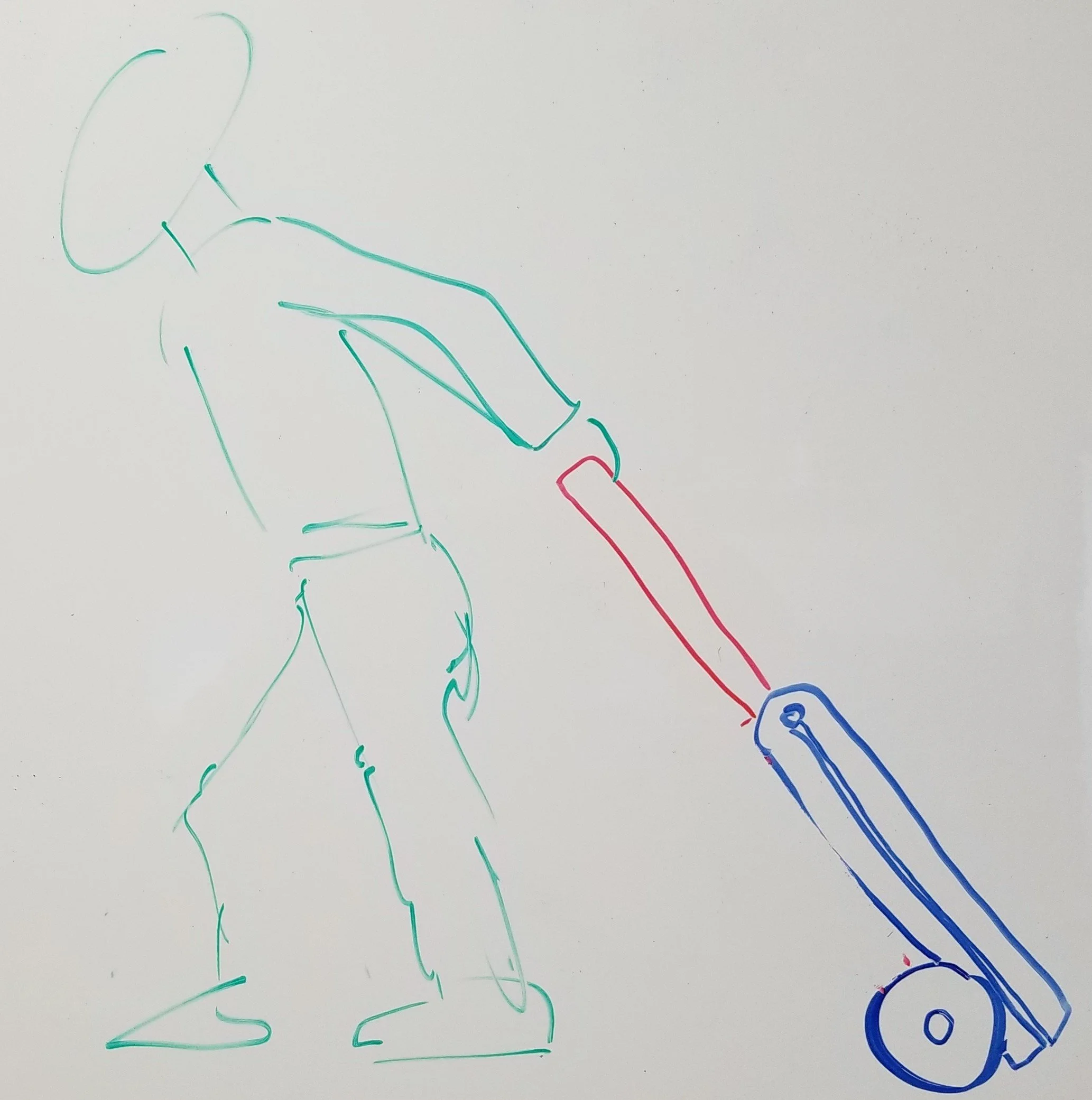

Our goal was to create a solution that addressed the difficulties of transportation, heavy weight, inconvenient folding for storage, instability in wind, and the wear and tear of sign-holding features.

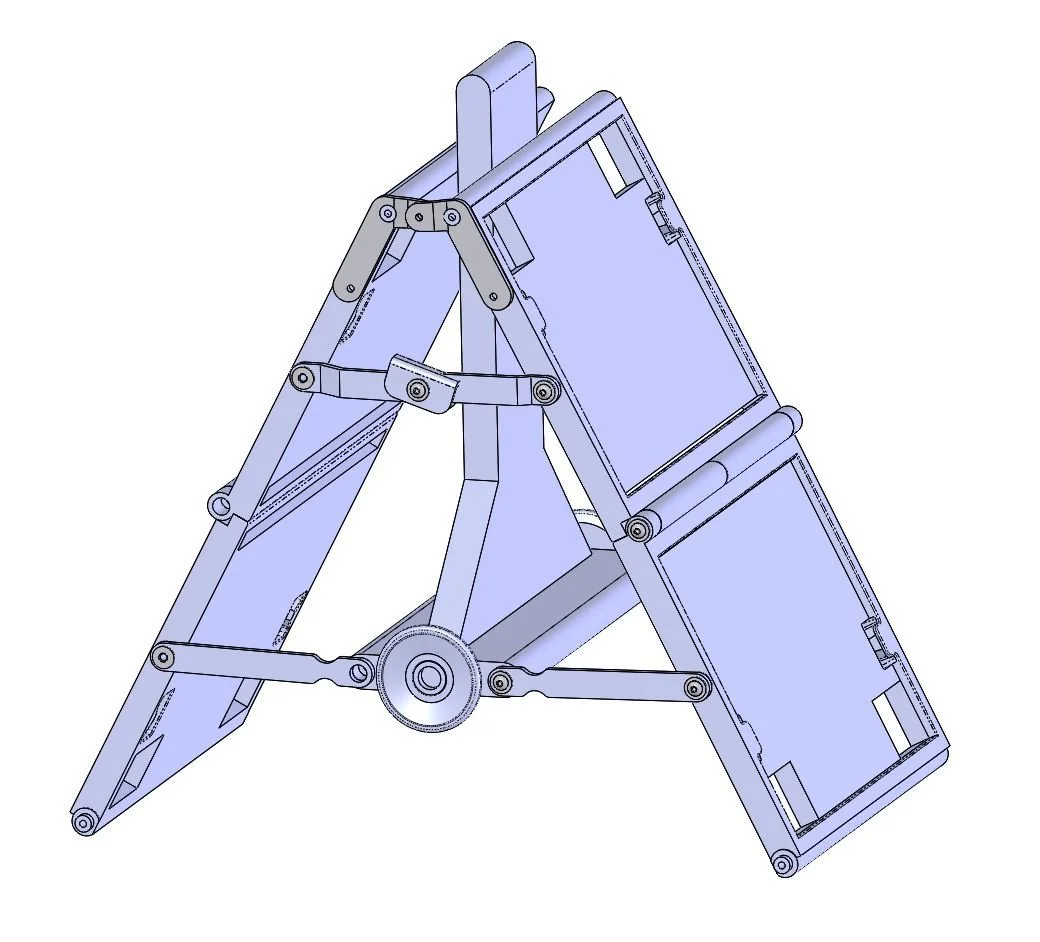

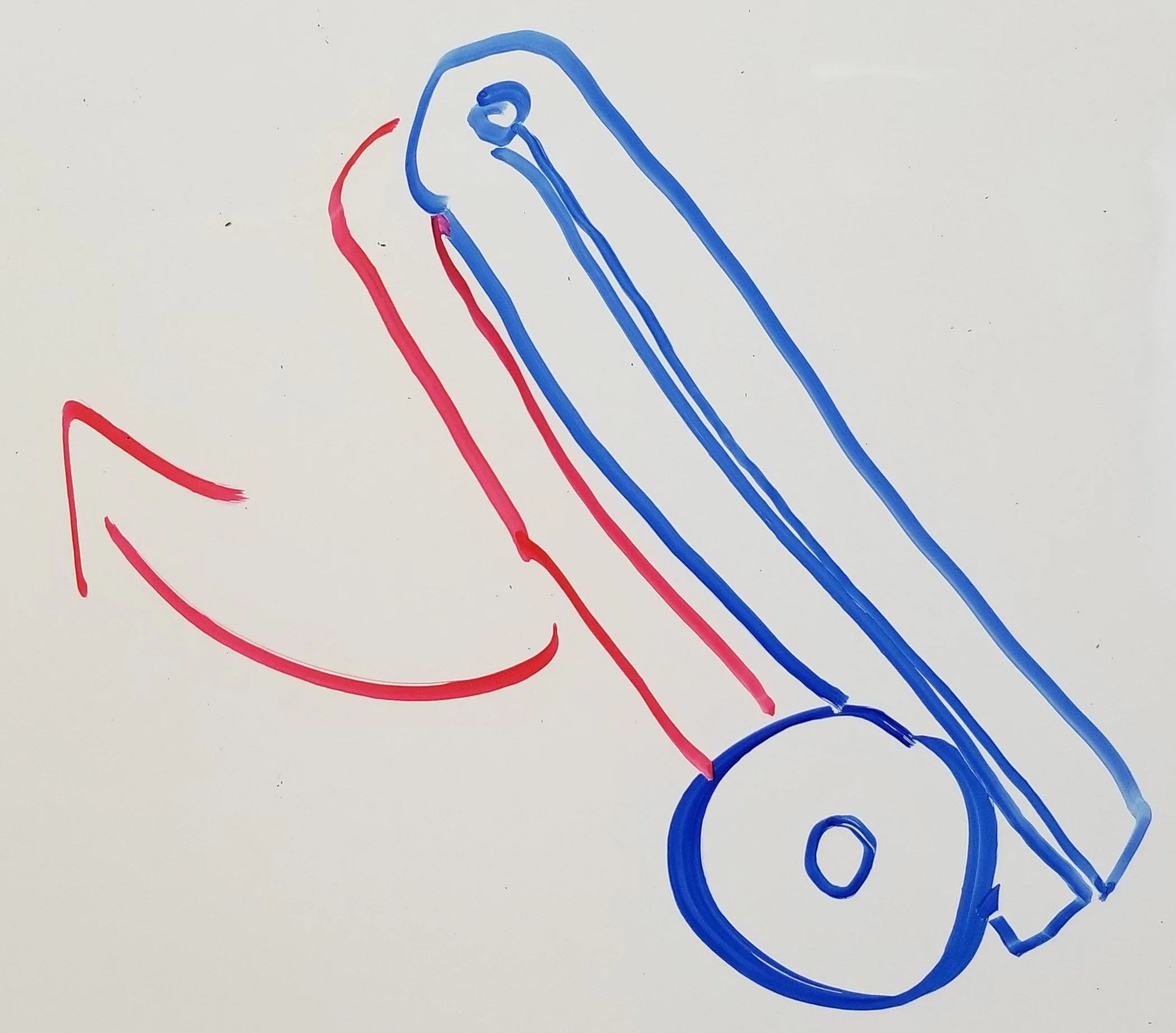

To start, we developed a visual rendering that resembled conventional sign holders. We then focused on the linkage/panel assembly, leading us to create a scale model and a 3D printed prototype. Although the prototype served its purpose, it consisted of numerous smaller moving parts, including an impractical inner component for the wheel and retracting handle.

Inspired to find a more efficient design, we went back to the drawing board. We proposed a 3-panel configuration, rather than the previous 4-panel setup, which allowed for the same number of signs to be displayed. This new design incorporated the wheel and handle onto the panels, reducing the number of parts required and making the sign holder lighter and less complex.

With approval from our client, we proceeded with the engineering phase, working towards production readiness. We developed a versatile part that could be used for any panel by strategically placing specific features. The panels were blowmolded and supplemented with auxiliary sheet metal and off-the-shelf components.

Our final blowmolding design proved to be manufacturable without requiring any functional changes. Throughout the manufacturing process, we provided continuous feedback and support.

The result of our efforts is a sign holder that offers easy transportation, thanks to its reduced weight and rolling wheels. It folds down efficiently for convenient storage and stacking. Its wider base and optimized weight distribution ensure stability even in windy conditions. The folding hardware features sturdy sheet metal linkages and hinges, providing durability and longevity, even with repeated opening and closing.