Prototypes that stand out

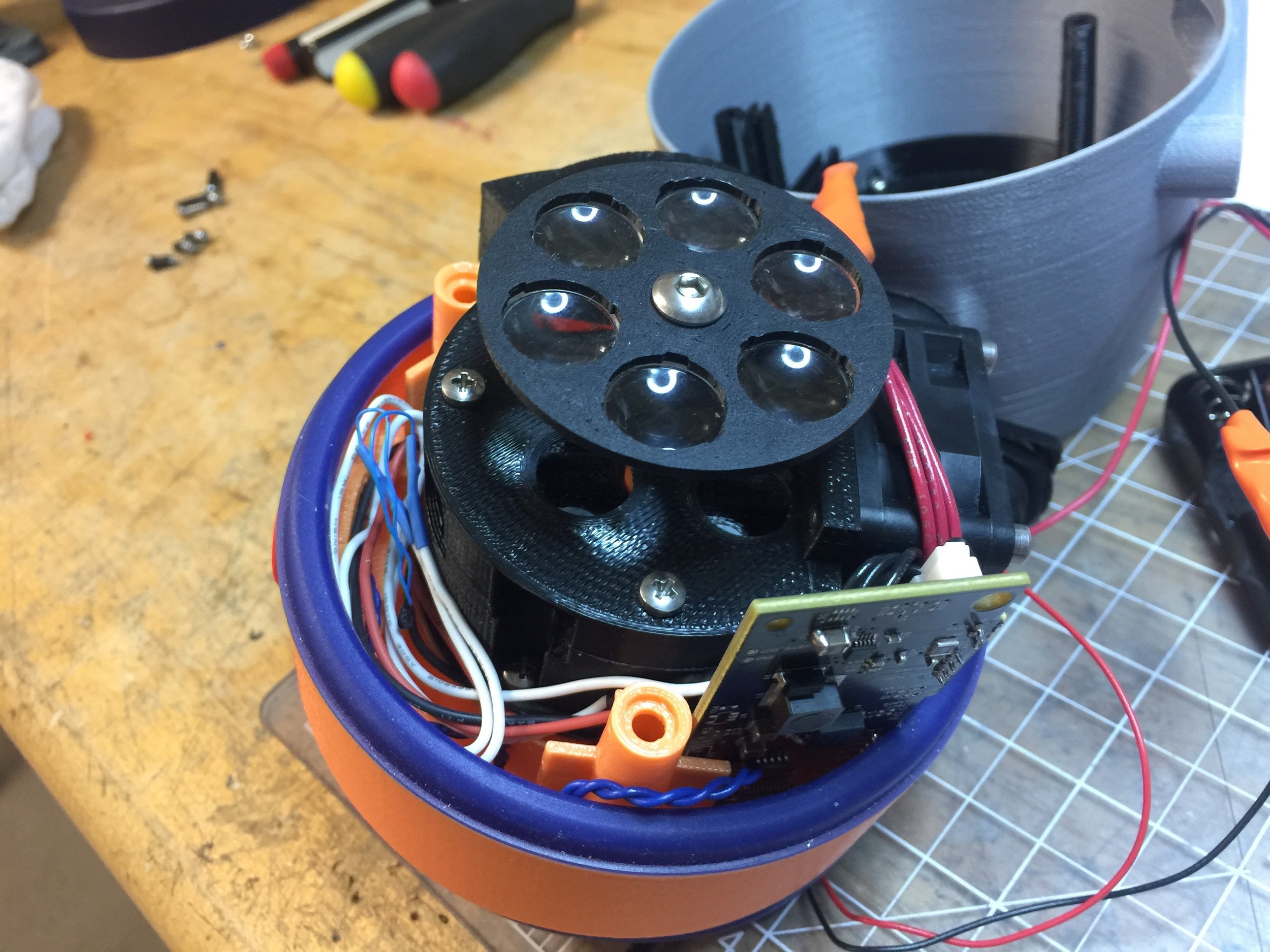

Functional and beautiful prototypes including plastics, metals, embedded electronics, and mechatronics.

Prototyping serves to prove an idea, test a concept and find improvements.

These proof of concept prototypes served as tangible representations of our innovative ideas, enabling us to gather crucial data and insights.

They allow us to validate fundamental assumptions and identify potential challenges or limitations. Through the iterations of prototypes, we can fine-tune designs, functionality, and performance to ensure optimal results in the final product.

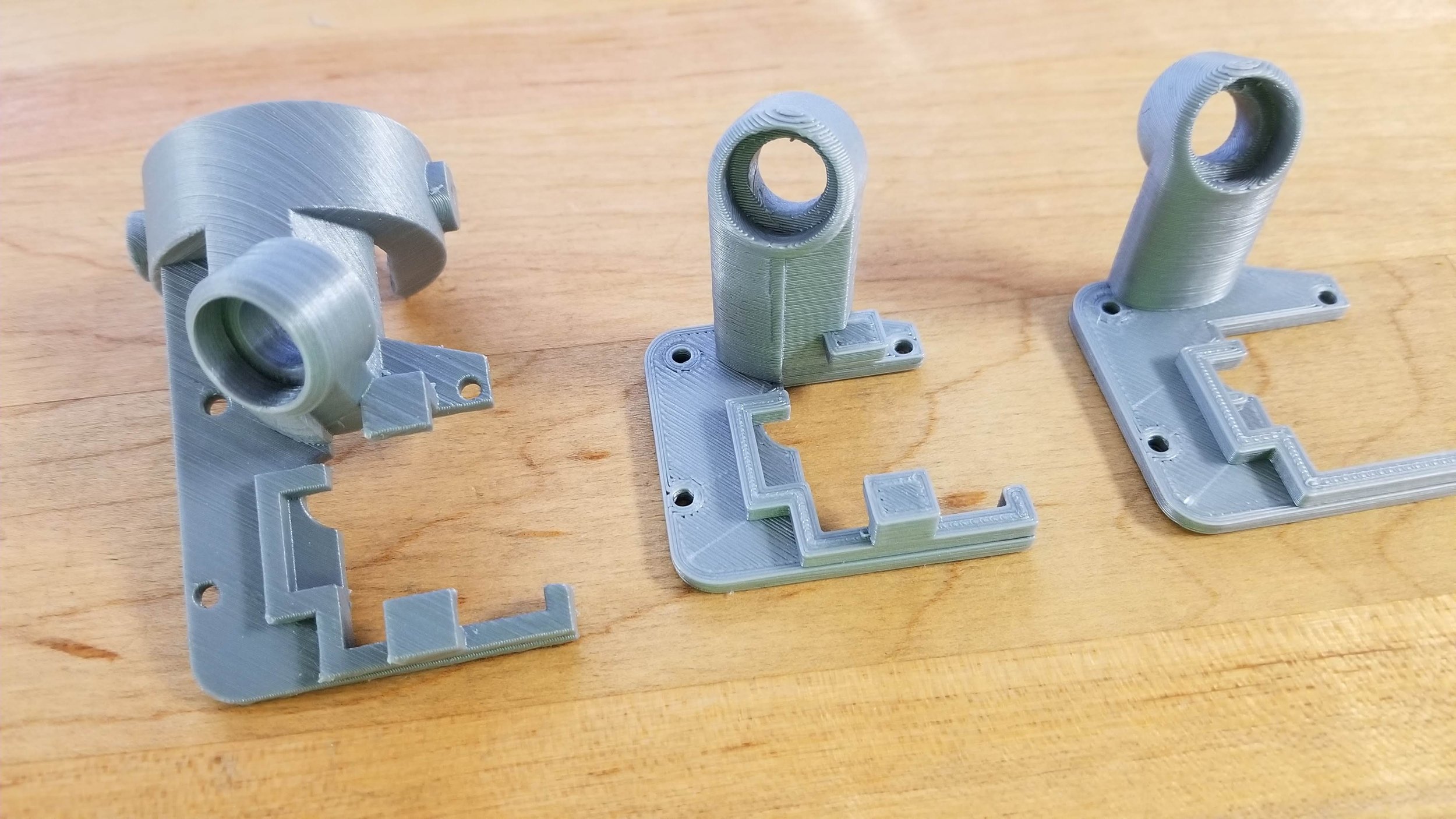

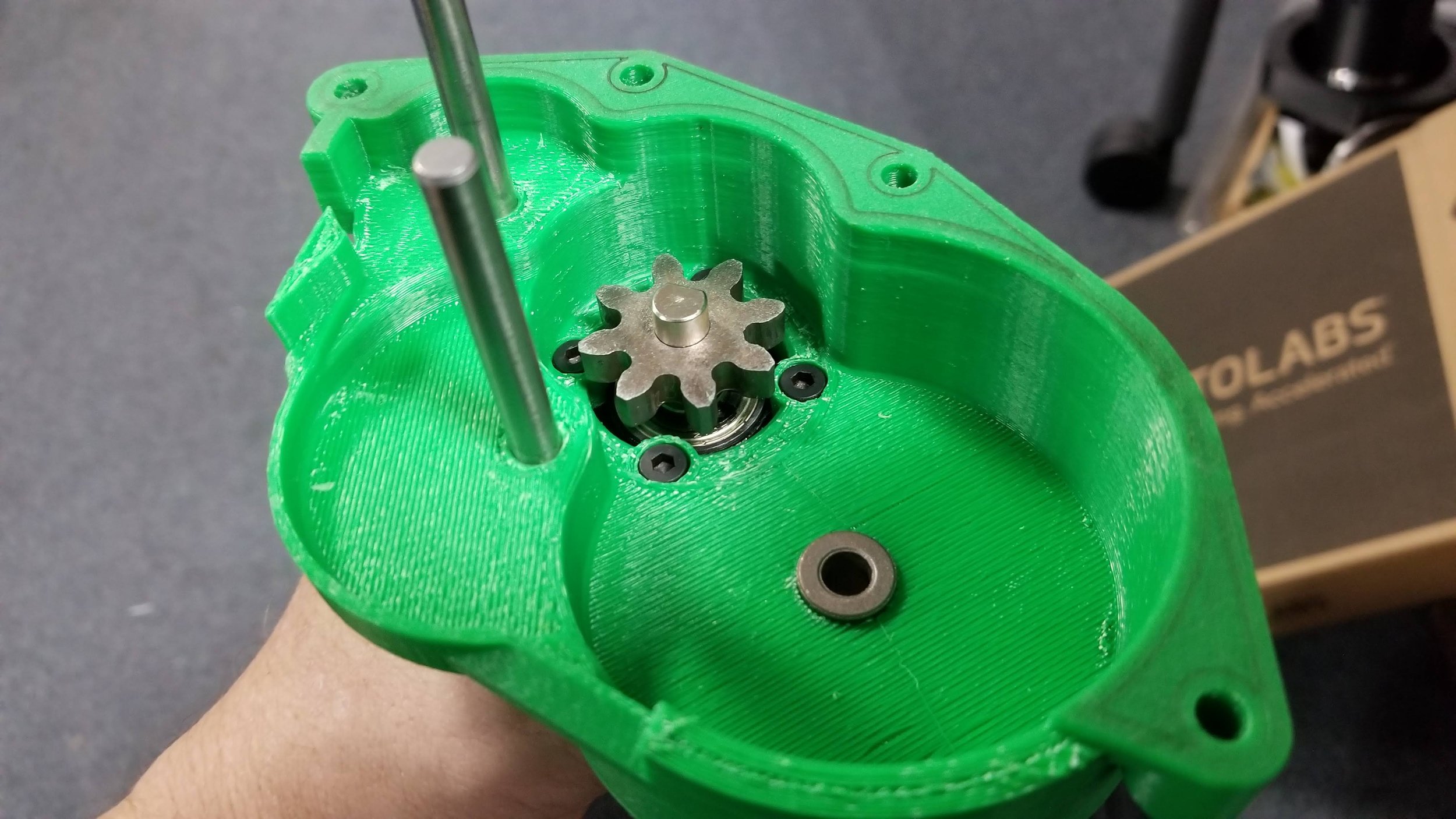

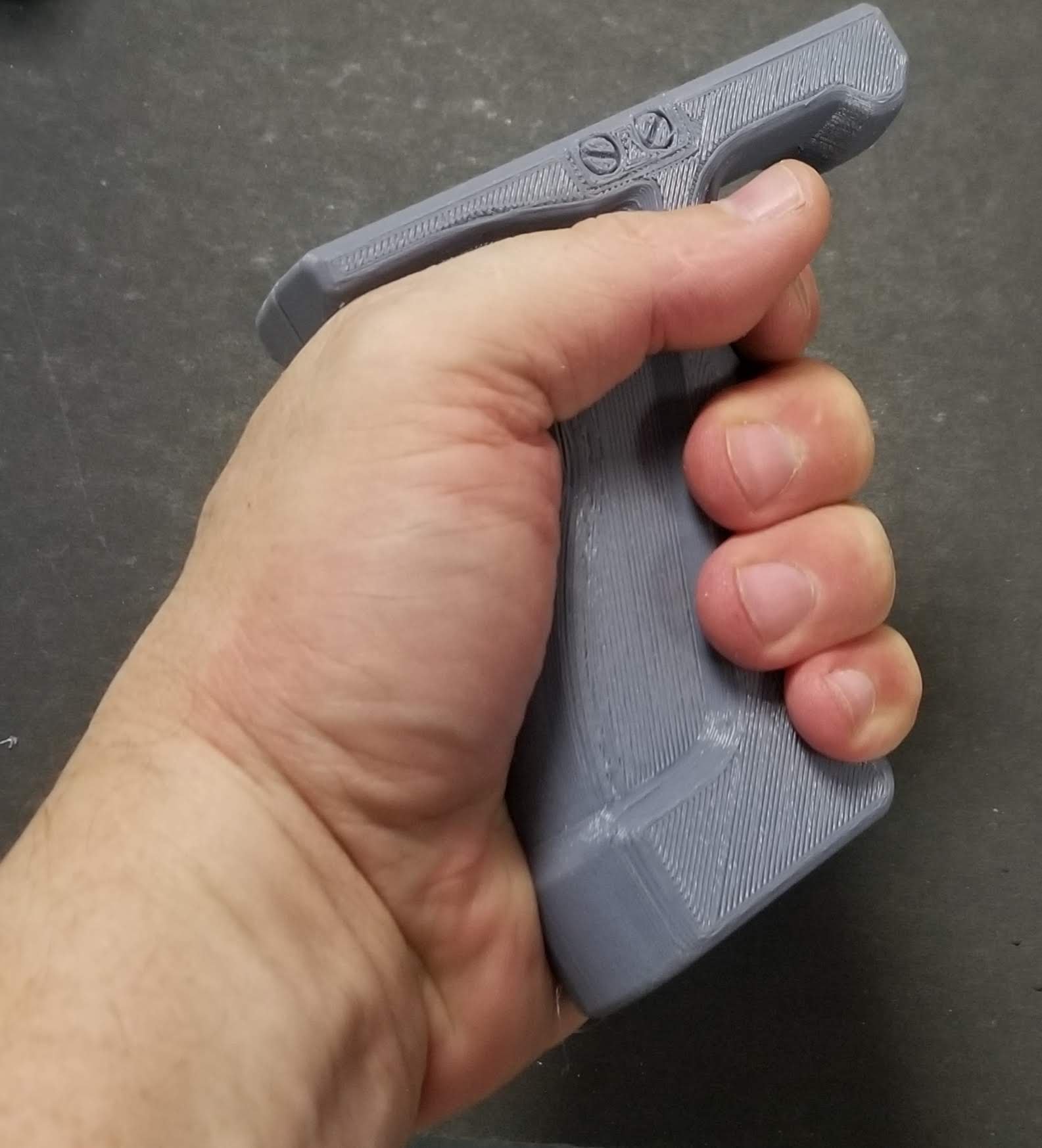

Types of prototypes

Physical prototypes come in many different forms based on their intended purpose. We have experience making prototypes for a variety of applications. All product development processes will involve at least one, but usually many prototypes of varying function and purpose. Here are some common categories of prototypes that we create.

-

Serves to test a particular / multiple components and their functionalities. Usually we focus on proving the most complicated and risky features first.

-

These prototypes are used for proving the concept and system functionality to investors. Sometimes they are made to also match the intended industrial design.

-

A prototype that looks great for marketing purposes. Usually there is at most limited functionality. Great for presales or crowdfunding.

-

The cream of the crop when it comes to traditional prototypes. Everything works as intended and the appearance is hard to distinguish from a production model.

-

First run models from the manufacturer that are used to tweak the process and troubleshoot any potential issues before volume manufacturing.

Processes we use

3D Printing

The simplest method of rapid prototyping for small - medium sized products made primarily from plastic. We employ 3D printing on almost every project because it is fast and inexpensive.

Laser Cutting

An easy way for creating 2D panels and precision gears. Many proof of concept prototypes involve a laser cut frame for stability and ease of modification.

CNC Machining

When 3D printing or laser cutting are not an option we use machining processes for working with plastics and metals.

Testing

The most common reason that we create prototypes for clients is so that their idea can be tested in the real world and feedback can be implemented into future iterations. We also have experience working with designated test labs for safety and design certifications.

Embedded Electronics

Arduino, Raspberry Pi, Custom PCBs and Firmware programming are commonly used in prototypes that combine mechanics and electronics. We provide these services directly so that you don’t need to find multiple providers.

Iteration

Prototyping is iterative by nature, meaning that each prototype is likely an evolution from previous models. We often find and fix problems on the fly when creating a new prototype. These issue are resolved so that the problem never occurs in the final product.

Prototype with us.

sales@creativeengineering.com

(914) 771-5540