Product: link

Client: Mike Tracy (Inventor)

Mike came to us with a problem: his prototype spring-powered sunglasses-retracting system worked, but the mechanism was bulky, & it was awkward to clip on & remove. He wanted to take his idea from a rough working concept to a slick, manufacturable consumer product.

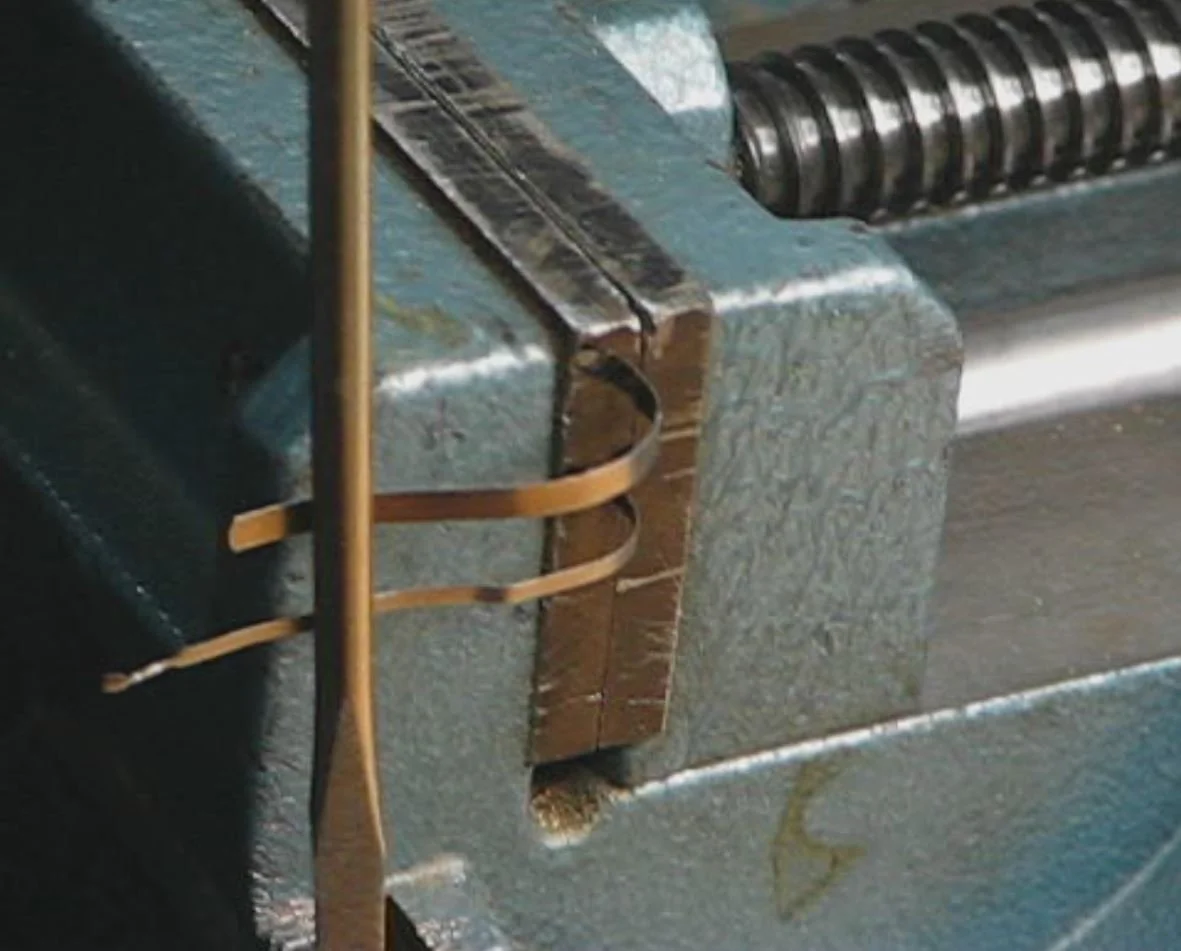

During our initial investigation, we found that the device’s internal coil spring could be substantially reduced in width without compromising its functionality or longevity. Using a thinner spring would allow us to improve the size & weight of the retractor a great deal, but the prototype already used the thinnest such spring readily available.

We contacted a coil spring manufacturer & (after some negotiation) convinced them to do a short run of material at the minimum width our testing had determined to be sufficient for the function of the device. With a custom-machined brass housing to take full advantage of the reduction, the difference was striking: the prototype went from a bulky protrusion to a slim, lightweight “button.”

With the confidence of a compelling prototype, Mike asked us to create the production-ready CAD data for his device, which was tooled & manufactured (along with a carefully-designed, low-profile coil spring).

Eyezgear is now a successful, patented, award-wining product that works as Mike envisioned, available in many stores & online shops with a 5-star Amazon rating.