CASE STUDY EXCERPT - From “A Life All His Own”, a “PTC Express” case study written by Amy Castor, freelance writer. December 2001

“Smart toys” have become mainstream since Hasbro-owned Tiger Electronics took the market by storm three years ago with Furby, the interactive talking pet. Stores couldn’t keep enough of them in stock. With sales in the millions, Furby marked the dawn of the interactive toy era.

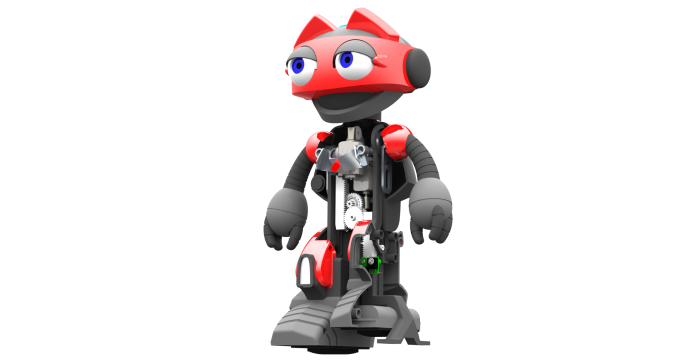

Now Tiger, the biggest player in the robotic toy field, has done it again — with Ottobot, a boy robot timed for the holiday shopping season.

Ottobot can walk across a coffee table without falling off or explore a room without bumping into walls. He interacts with people and other Ottobots. Put two robots together and they’ll dance, tell each other “knock- knock” jokes, and break into giggles.

Making an electronic toy poses a host of challenges that stuffed dolls and playhouses never did. Ottobot designers faced a constant struggle between style and function. Thanks to Pro/ENGINEER, they were able to design and package all the robot’s necessary parts while keeping costs at a minimum. Ottobot retails for around $30 (US).

A tight squeeze.

“It’s like a Swiss watch in there,” said Paul Dowd of Creative Engineering, who was hired to create the CAD design for the toy. His assignment: get parts to fit without changing the toy’s appearance.

Dowd was given hand illustrations, a set of crude foam sculptures, a breadboard walking mechanism, and written specifications. These elements had to be integrated into a manufacturable, functional, and affordable product — no easy project. Packaging was tight. There was little room inside the 7-inch frame for the robot’s motors, gears, infrared (IR) sensors, PC boards, and other parts.

Another challenge was integrating style and function. The robot’s legs, for example, not only had to look good but also had to propel the robot and house the IR sensor (one in the right knee for object detection).

“I did a lot of iterations,” said Dowd. He concentrated on the torso, where he continually changed the master and updated parts, tweaking the design a millimeter at a time to make things fit.

For these tasks, Pro/ENGINEER’s parametric nature allowed plenty of design flexibility. At the same time, Pro/ENGINEER let Dowd check onscreen exactly what his product would look like.

Sketch to skeleton.

Design was a back-and-forth process. “You don’t know all the problems until you start putting it together,” Dowd said. “As I began adding parts, I had to modify the framework — changing it, redefining it, and moving it around.”

Dowd began by modeling a rough skeleton framework in assembly mode. He used datum curves to represent moving parts, such as articulated joints, motors, and gears. As he finished modeling parts and subassemblies, he brought them into the main assembly and used the datum curves to constrain them. Because packaging was so tight, he often had to try out several design iterations before he found one that worked.

To see how parts worked together and check for interferences, Dowd wrote assembly relations that articulated his skeleton. He drove these equations with a user-defined parameter he called “time.” Changing “time” from “0” to “1” moved the robot through a complete walk cycle; 0.25 represented half a step.

Using a mapkey, or keyboard macro, to automate menu picks, Dowd was able to move the robot’s legs quickly to any position. (The mapkey would pause to allow an input for “time” and then regenerate the assembly.) Dowd noted values that represented extremes in position, such as “leg fully retracted” or “leg fully extended,” and checked them frequently as his design progressed.

“I was able to model all those relationships using this assembly relations technique, which is invaluable when doing interference checks in all different positions,” said Dowd. “And results are immediate because I’m right in assembly mode.”

The perfect surface.

Ottobot’s sculpted body is manufactured using injection-molded plastic parts. Dowd used Pro/ENGINEER’s Advanced Surface Extension (ASX) to create the toy’s outer surfaces. ASX not only allowed him to model these complex shapes but also gave him greater flexibility in shelling the thin-walled parts.

The shape of Ottobot’s legs, for example, was too complex to shell in a single operation, as solid modeling would have required. With ASX, Dowd was able to offset different pieces of the leg individually — the thigh, lower leg, and foot — and then merge the resulting core surfaces.

Because plastic products commonly have a nearly identical right and left side, Dowd used a master model technique to create each of Ottobot’s sides. He created a “single master” of the left side, duplicated it with a “master merge copy,” and then used a “master merge mirror” to create the right side.

The end result was a master model that had geometry common to both sides. To model features unique to either the right or left side, like male and female screw bosses, he used the “merge copy” and “merge mirror” parts.

A collaborative effort.

Beyond Dowd’s CAD modeling, an enormous amount of collaboration went into creating Ottobot. An outside inventor, Andrew Filo, supplied the original concept for a walking mechanism. Aesthetics were the brain child of Jason Eastman, Tiger senior brand manager. Hasbro’s Hong Kong office provided specs for the circuit boards and did all the wiring. Hasbro Advanced Development Services, led by Adam Craft, coordinated the project.

Throughout the design process, Dowd stayed in frequent contact with the Hasbro team. On various occasions, he sent screen captures, 3D DXF files, and Pro/ENGINEER data (revved as 10, 20, 30, and so on, for version control). According to Eastman, being able to view Ottobot in 3D allowed him to evaluate the aesthetics easily.

At the end of the project, the hard work and numerous iterations made all the difference.

“This is the first robot just for kids,” said Adam Craft. “It’s extremely maneuverable, and for this price, it does a lot.”

OVERVIEW

Given the constraints of the robot’s look and cost, we collaborated with Hasbro to develop numerous mechanisms that fit into the toy without interrupting the electronics or aesthetics, enabling Ottobot to walk, dance, talk, move its limbs, and sense its environment.

MORE INFO

Problem: Given an extremely compact packaging envelope with a defined exterior appearance, a breadboard walking mechanism, and product specifications, design a toy robot that sells for under $30.

Solution: The Ottobot, a toy robot that employs gearing and mechanisms packaged tightly into injection-molded, contoured housings.