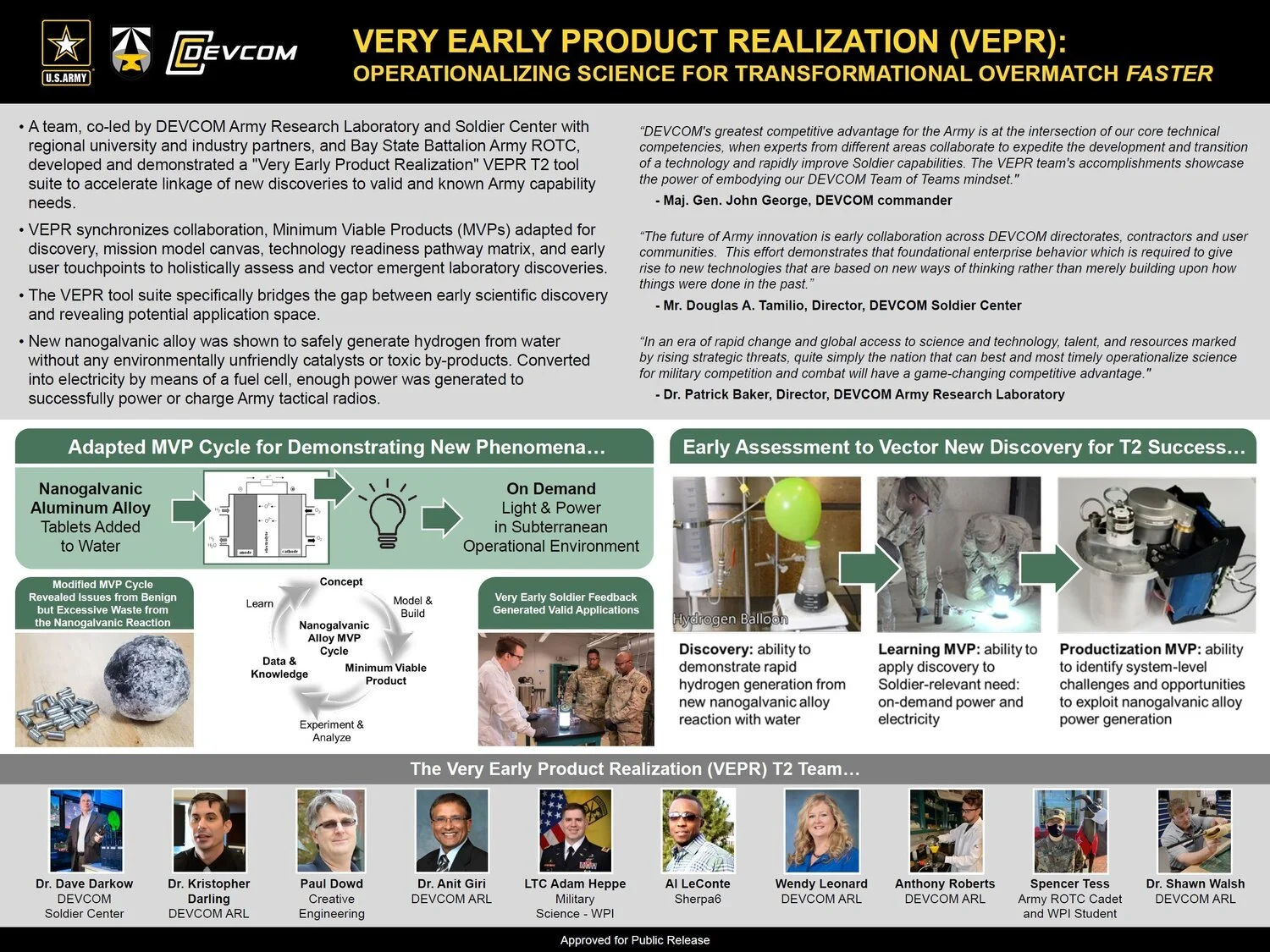

THE PROBLEM

The US military is always looking for new ways to generate green electricity for soldiers on missions or in emergency situations. They had developed a material called Nanogalvanic Aluminum, which creates hydrogen when mixed into water. However, instead of hydrogen, they wanted electricity. So they brought their problem to Creative Engineering: how do you make a generator that runs on Nanogalvanic Aluminum?

REQUIREMENTS

The military was looking for a device that:

Is small enough and light enough to be carried around by a soldier in the field

Runs as long as possible without needing to be refueled

Has the aluminum sealed in a convenient package that fits right into the device

Generates enough power to run a standard radio while simultaneously charging the radio’s battery

THE SOLUTION

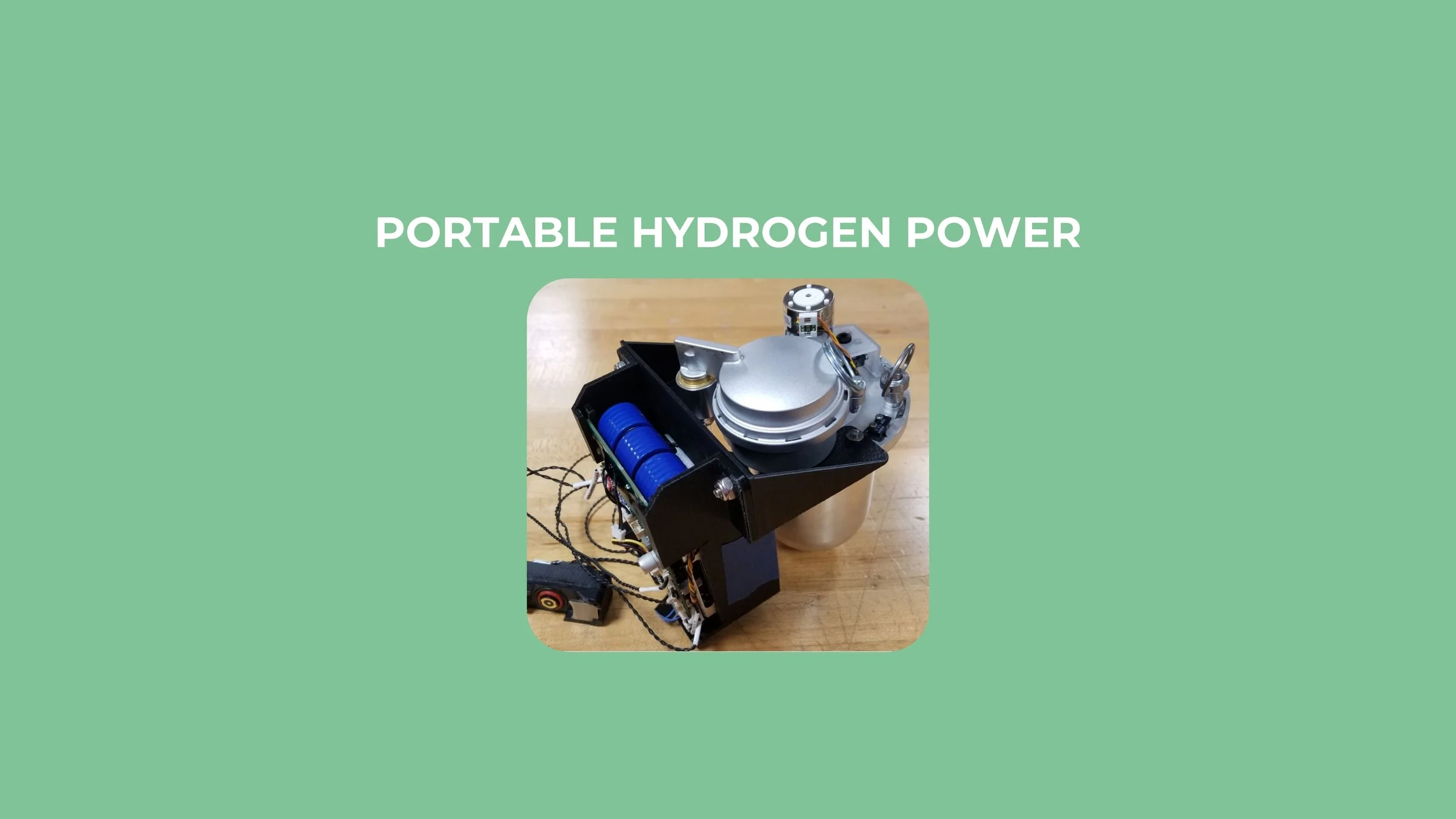

With these challenges in front of us, we developed the SNAP (Soldier Nanogalvanic Alloy Power) system.

The core of the device contains the system that outputs the aluminum into water. We developed a convenient method of forming the aluminum, which comes as a powder, into pellets, and sealed the groups of pellets into packages. The soldier simply needs to load one strip in the device and a bit of water. As the device runs, the packaging is cut open one group at a time, releasing the exact amount of aluminum needed into the water to keep power flowing and allowing the device to run autonomously until it runs out of aluminum. Then the soldier refuels by sliding in a new strip and adding a bit more water.

Once the aluminum hits the water, it creates an abundance of hydrogen gas. The other system in the device funnels that hydrogen into an off-the-shelf fuel cell, which uses it to generate enough green energy to keep the soldier going. Because you don’t need clean water to make the device go, the soldier doesn’t even have to carry water with them; they can use whatever they find in the field, further increasing the portability.

To power the radio, a custom circuit board was designed and programmed. The board manages the power going to and from various parts of the system such as the fuel cell, a capacitor bank, a small buffer battery, the large radio battery, or the radio itself. The power is distributed based on what needs charging at any given time. The software also "decides" when to create more hydrogen, manages the dispensing mechanism, and monitors pressure and temperature in the reaction chamber.

THE AWARD

The SNAP System was awarded a 2021 Technology Transfer Innovation Award from the Federal Laboratory Consortium for showing the effectiveness of the military working with a civilian company to develop new technologies.

See some of our other military projects: