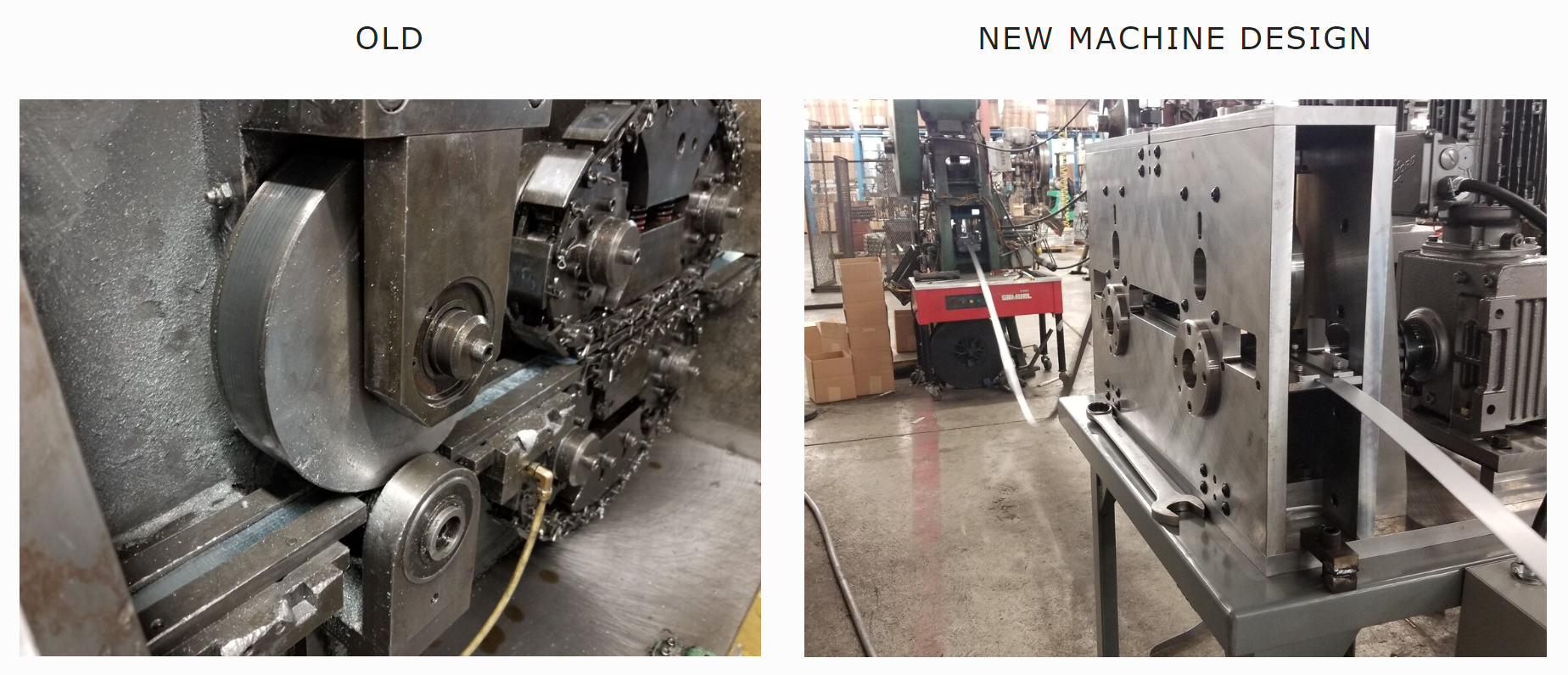

Independent Metal Strap Co. produces a large quantity of textured metal straps daily, using a machine that rolls the texture onto a long metal strip. Unfortunately, they were burdened with a machine that had been in service for over 10 years, produced by a company that had since gone out of business. This machine was also not meeting their needs. It used a massive “tank tread” chain to grip the metal strip, which was a nightmare to maintain, all the working parts were unstable because they were cantilevered off the main body with no support, and the method to change worn tools was so laborious that the downtime was measured in hours on a machine that needs to run 24/7. Creative was tasked with not just reverse engineering this machine, but making it better.

In just 6 weeks, both on schedule and under budget, we had designed a machine that not only did the work of their previous model, but had numerous additional improvements including:

Improved Usability and Maintenance

A series of two gripper wheels hold the metal strip instead of a large chain, making maintenance a breeze

Motors and gears for gripping and deformation are controlled separately to allow for independent fine-tuning of each action

The design makes the tool easy to remove once it’s worn out, reducing downtime from hours to mere minutes

Improved Stability

A multi-plate body design removes the cantilevered surfaces, greatly increasing stability with short load paths

Compatibility with existing parts

Utilizes the same drive shaft parts including bearings so existing stocks could be used for maintenance