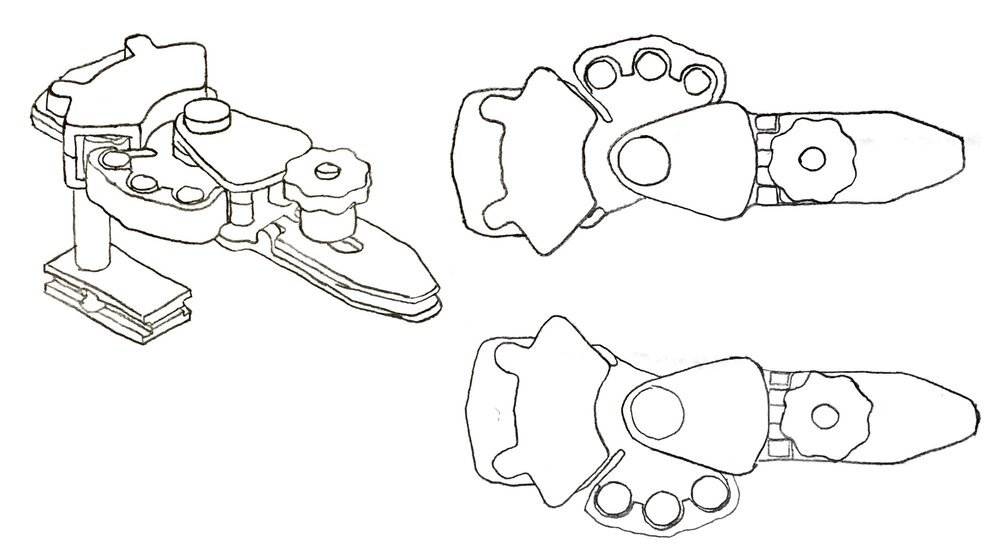

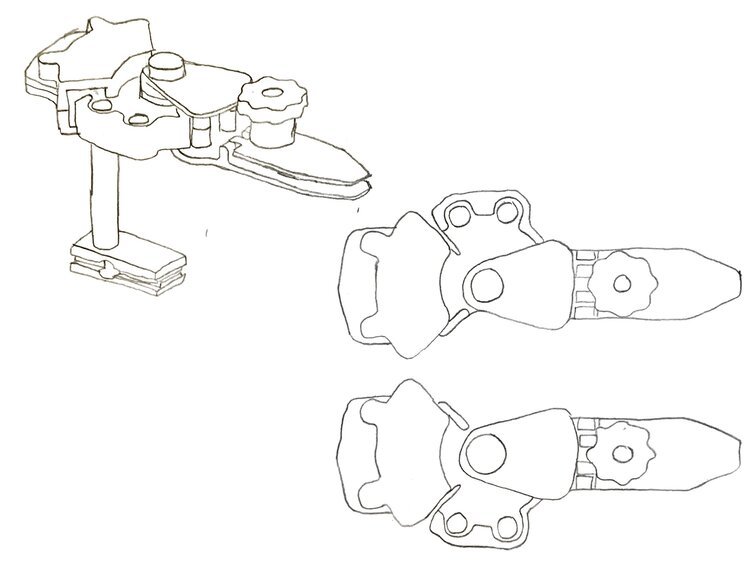

A variety of methods for holding a ligament graft specimen under tension while enabling the attachment of a continuous loop of suture to it had been developed and patented by a surgeon. The primary issue being addressed was the need for a second person to hold the tension and switch hands as the suture is swapped from one side to the other, as one strand of the suture material had to repeatedly pass onto either side of the ligament.

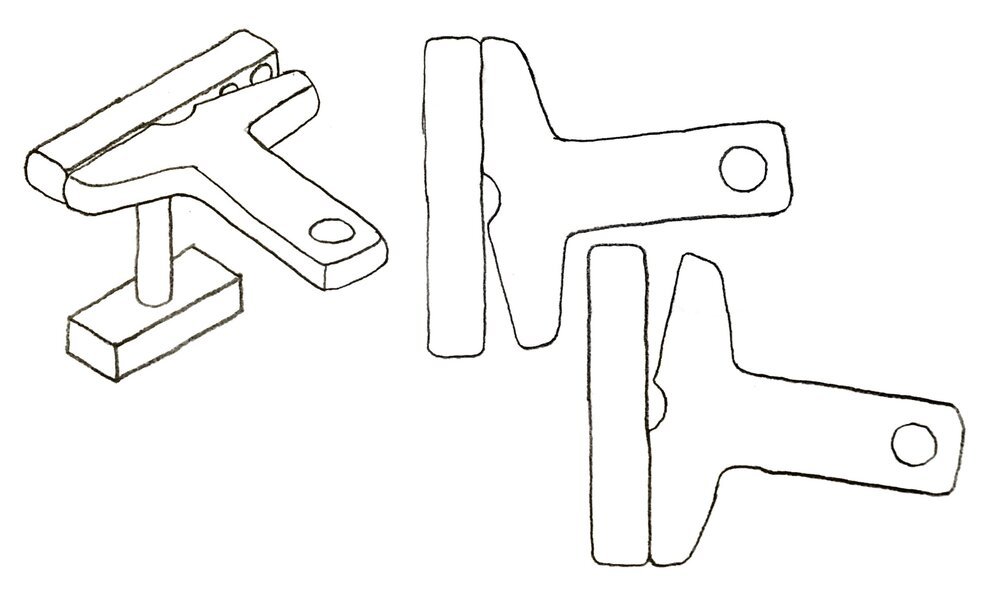

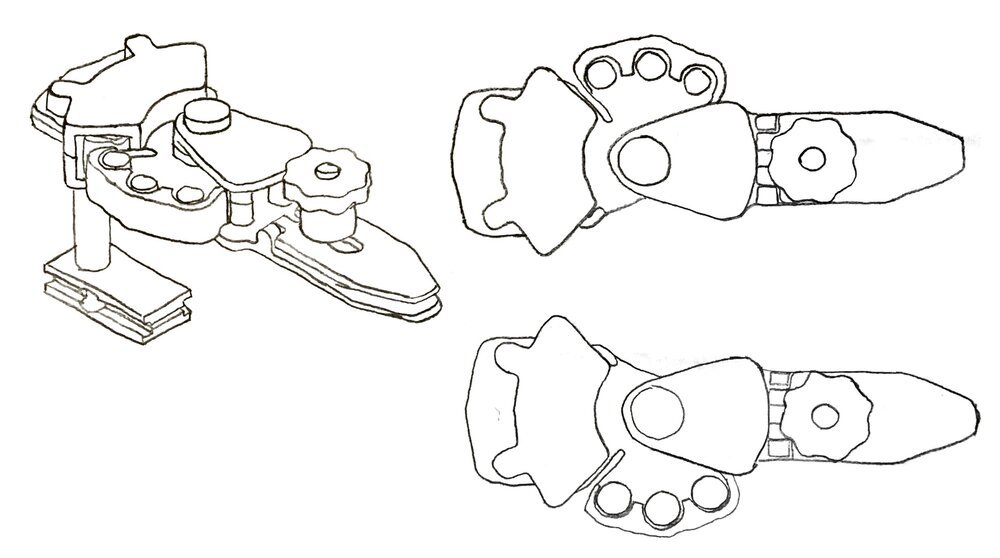

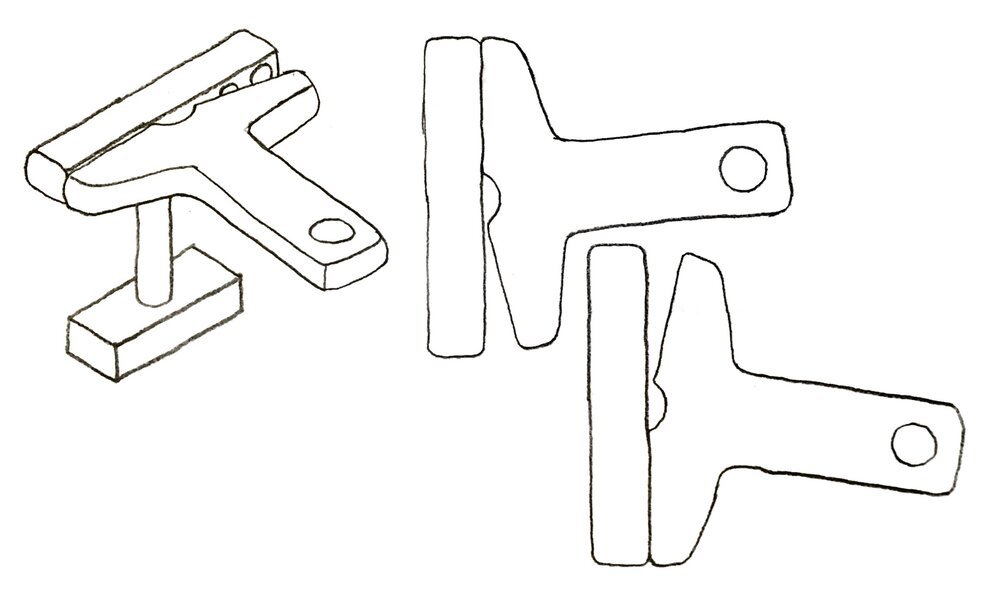

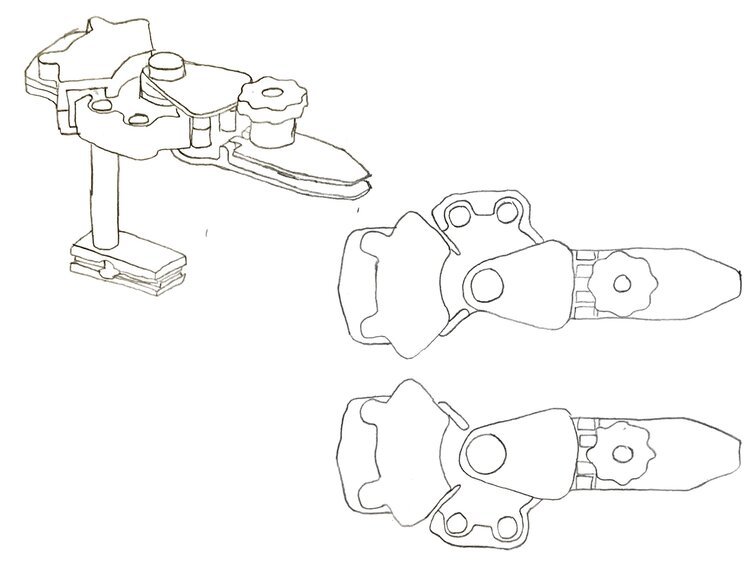

Upon learning about the challenge, research was done on shaft passers, a device allowing a spoked wheel to rotate even when a shaft passes through the spokes. This led to the development and prototyping of various solutions using 3D computer-aided design (CAD) and an in-house 3D printer farm. Subsequently, the design was refined, and the engineering was finalized, resulting in the creation of a working sample crafted from stainless steel.