SUMMARY

Flexon Industries reached out to us to help develop an injection molded hose handle. We were tasked with designing a handle that would look good and work well.

INDUSTRIAL DESIGN

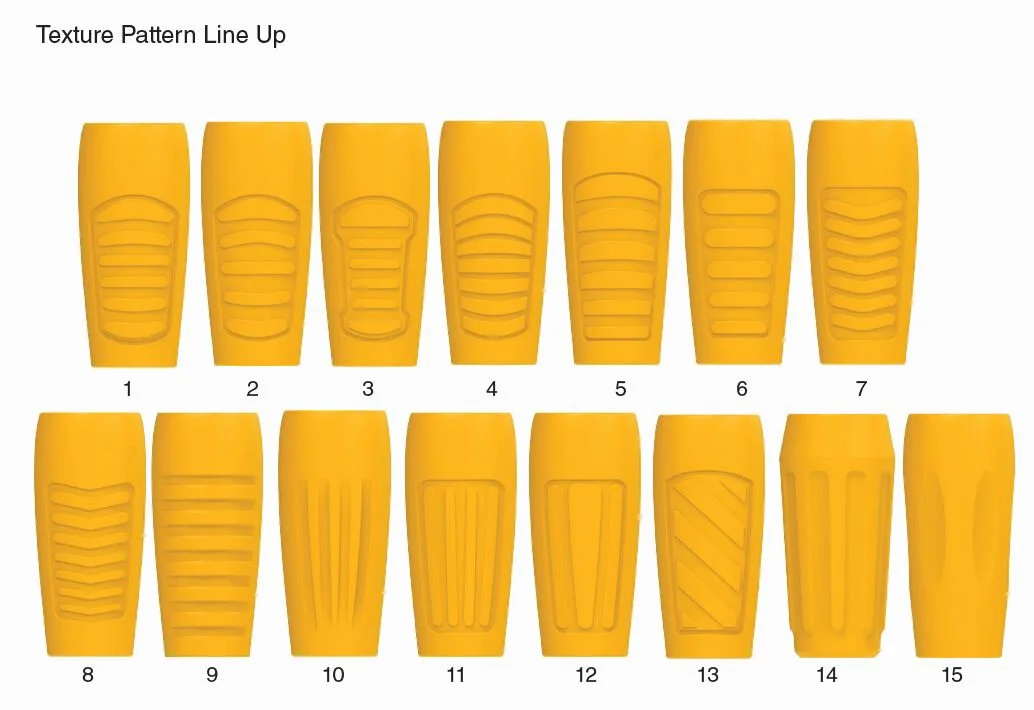

We started by exploring different looks within the overall aesthetic that was already pretty well established.

DESIGN FOR PLASTIC INJECTION MOLDING

As a high volume item, this required careful consideration before going to tooling for:

Plastic use: a small difference in plastic per part can lead to much lower cost over time at high volumes

Strength: we had requirements for the amount of torque the part needed to withstand, and had to balance this requirement with the others

Fits: everything has a tolerance, and we built in grooming ribs to allow subtle adjustments to the fit that would be quick and easy to make in the tool if needed

Molding direction: we carefully picked the parting line to allow the texture and logo, with an action for the center hole

MANUFACTURING SUPPORT

As is often the case, the tool maker for the injection mold requested some updates to the design to accommodate some of the more subtle molding requirements. We stayed in the loop to make those updates and see the project through to manufacturing.