Plastic Part Design

Truly functional custom plastic parts designed by U.S.-based engineers with real-world designed for manufacturing expertise. No-nonsense, highly capable engineering for any shape and any process to make your product’s needs a reality.

Folding Sign Holder designed by Creative Engineering.

Visit the case study to learn more.

Get in touch

Smarter, Functional, Manufacturable Plastics Design

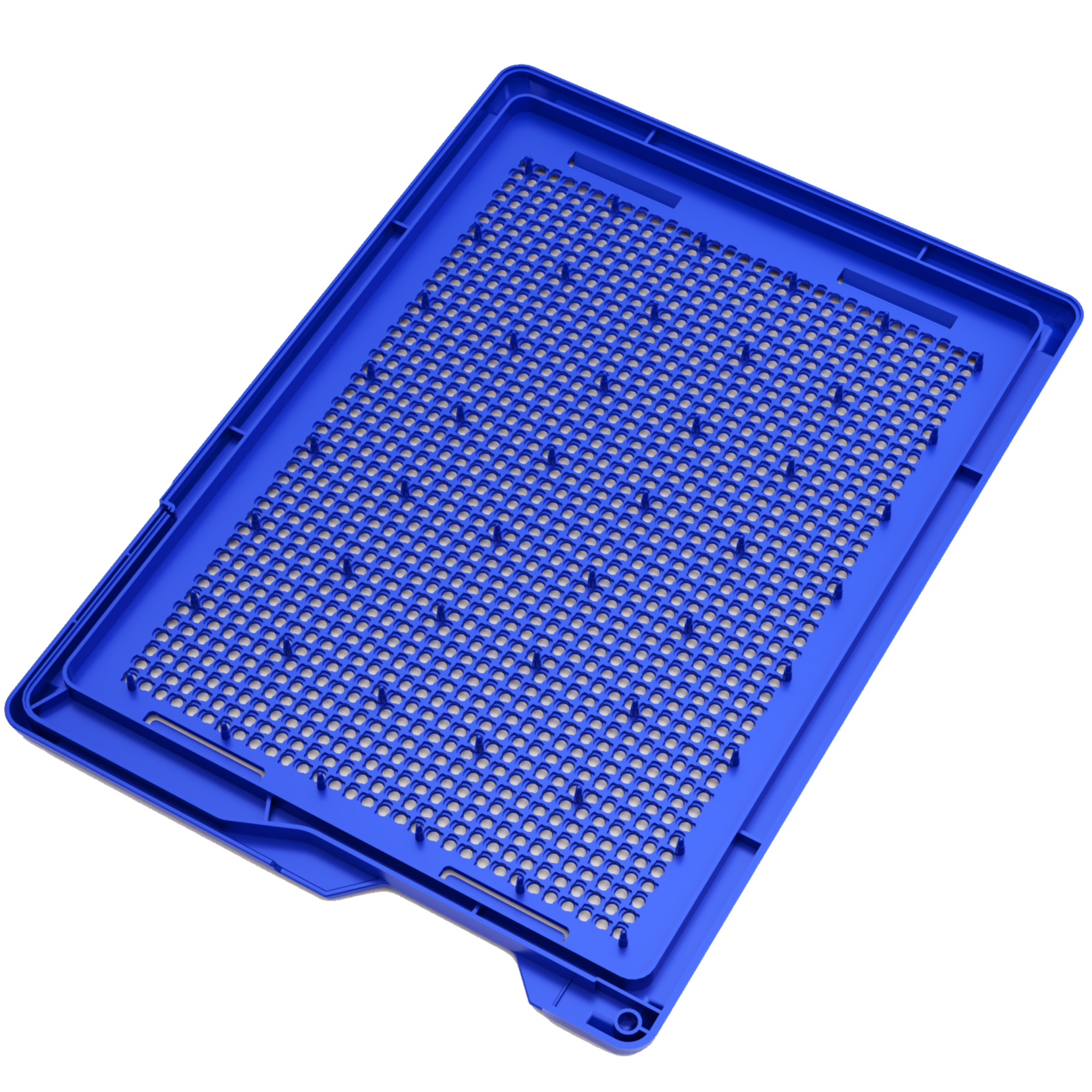

Braille Doodle teaching toy designed by Creative Engineering.

Custom Letter Opener designed and manufactured and by Creative Engineering.

Visit the case study to learn more.

What We Do

We provide full lifecycle machine development—from concept through installation—with engineering precision and production-level reliability.

Automatic Pet Feeder and Sifting Litter Box designed by Creative Engineering.

Our capabilities include:

Injection molding design

Additive manufacturing design

Rotational Molding

Blow Molding

Overmold Design

Electromechanical Products

Mechanical design

Full turnkey projects (design → fab → manufacturing → install)

Proof of concept models

Looks like - Works Like prototypes

Prototyping & pilot machines

Reverse engineering

Industrial Design

Manufacturing support

Complete documentation packages

Product Packaging

Premium, No-Nonsense Design for Manufacturing

Our team brings decades of hands-on engineering and manufacturing experience. Every design decision is made with real-world constraints, project needs, and project budget in mind.

U.S.-Based Engineering

All engineering is performed in the United States for better communication, accountability, and quality control.

Faster Turnaround

Our lean, focused engineering approach eliminates unnecessary delays—ideal for projects with medium to long timelines (4–15 months) requiring consistent progress, clarity, and tight management.

Experience With All Client Types

From Fortune 500 companies to defense programs to early-stage product companies, we adapt to the scale, documentation, and rigor your project requires.

-

Every project begins with discovery and defining the project. We work directly with you or your engineering, marketing, and production teams to capture all functional and non-functional requirements. This includes performance targets, customer experience, safety considerations, cost targets, shelf space, utilities, operator interactions, branding requirements, and integration with existing products.

We also evaluate any existing competitor products, samples, fixtures, or parts to fully understand real-world constraints before design begins.

-

Our team generates multiple concepts to determine the most effective path forward. This phase may include mechanism studies, competitor analysis, preliminary CAD, assembly evaluations, relative cost assessments and project risk identification.

We present concept options with pros/cons, layout drawings, preliminary CAD, and projected costs. By the end of this phase, the product’s functionality, approach, and costs are clearly defined and aligned with your goals.

-

In the preliminary engineering phase we will work with your team to translate goals into clear technical requirements, explore concepts, and assess feasibility across performance, cost, risk, and manufacturability. This phase focuses on understanding the problem at a systems level to identify constraints, key variables, and critical unknowns.

We will build our first prototypes during this phase, often rapid prototyped 3D printed parts, allowing us to test our assumptions the real world and provide tangible units for our clients to try before committing to a final concepts. Our extensive experience with 3D printing and in-house equipment allows us to quickly get valuable feedback and improve our designs.

-

Once a prototype is approved, we transition into full 3D mechanical design. This includes:

Complete CAD modeling of all mechanical components

Detailed mechanism design with tolerances and GD&T where applicable

Purchased component selection (screws, gears, shafts, bearings, springs, etc.)

Full electrical schematics where applicable

Engineering drawing package

Throughout this phase, we hold regular design reviews to ensure alignment and transparency.

Our Process

-

We can manage other parts of your project besides just engineering for a full turn key, one stop experience for your product development needs.

This includes:

Industrial design

Brand identity

Patent support

Packaging design

Regulatory testing

Human factors and UX design

-

Choosing the correct the manufacturer ensures your plastic part is built exactly as intended at the correct cost. We will use our network of tested and reliable manufacturers and choose the one that best meets your business needs from order size, material, and timeline.

We act as the technical bridge between your design team and the manufacturer, translating engineering intent into clear, production-ready documentation. This includes detailed drawings, tolerances, material specifications, and critical quality requirements, along with direct communication to clarify tooling assumptions, molding constraints, and process details before anything is cut.

Throughout this phase, we work hands-on with the manufacturer to review DFM feedback, resolve questions, and prevent misinterpretations that lead to costly errors or rework. By proactively managing these conversations and validating decisions early, we protect design integrity, reduce production risk, and ensure what gets manufactured matches what was engineered.

-

After placing your first order, we will receive the first completed parts. They will be inspected and tested in detail to ensure compliance with the drawings and other files sent to the manufacturer. They will also be tested for function and ensure that the products you receive will be exactly as you ordered them.

Certain predetermined critical to function features will be progressively groomed, as the mold will be slowly dialed in until the feature in question is perfectly sized for its function.

-

Once the first articles are approved by you, the full order will be started, and we will create work instructions for the manufacturer to correctly and consistently assemble and package your final product, allowing you to receive a complete, ready for sale product quickly and without errors.